Aluminum alloy skirting

Category:

Decorative Aluminum Profiles

Aluminum alloy skirting

Description:

1. Material Performance Advantages

- Lightweight, High Strength, and Durable: With a low density (about 2.7g/cm³), aluminum alloy is easy to install while maintaining excellent impact resistance and rigidity, resisting deformation from collisions or extrusion to ensure long-term structural stability.

- Excellent Corrosion Resistance: The natural oxide film or coating on the surface withstands moisture, water vapor, and daily acid-base substances, making it ideal for humid environments like bathrooms and kitchens, preventing mildew and rust.

- Fire Resistance and Weather Resistance: As a non-combustible material, it meets building fire safety standards, neither burning nor releasing toxic gases when exposed to open flames. It adapts to temperature changes from -50℃ to 150℃, remaining crack-free and deformation-free in outdoor or high-temperature difference areas.

2. Decorative Advantages

- Simple and Modern Design: Diverse cross-sectional designs (right angles, arcs, grooves, etc.) feature smooth lines, matching various styles like modern, Nordic, and minimalist to enhance overall space texture.

- Diverse Surface Treatments:

- Anodizing: Presents metallic original colors (silver white, champagne gold) with a delicate, wear-resistant finish.

- Powder Coating: Available in rich colors (black, white, gray, wood grain, etc.) to harmonize with walls and floors.

- Fluorocarbon Coating: Ideal for outdoor use, ensuring long-lasting color without fading.

- Wood Grain Transfer: Imitates solid wood texture while combining metal durability with natural aesthetics.

- Natural Visual Transition: As a decorative connector between walls and floors, it covers gaps and beautifies boundaries, creating a softer spatial transition.

3. Installation and Maintenance Benefits

- Convenient and Efficient Installation: Standardized production allows customization according to wall dimensions, fixed by clips, screws, or non-marking glue, suitable for both new constructions and renovations with short construction cycles.

- Low Maintenance Cost: Smooth surfaces resist dust accumulation, requiring only a damp cloth or neutral cleaner for cleaning. Unlike wooden skirting, it eliminates the need for regular waxing, saving long-term maintenance efforts.

- Recyclable and Environmentally Friendly: Aluminum alloy is 100% recyclable, with high regeneration efficiency, aligning with green decoration concepts.

4. Functional Practicality

- Protect Wall Bases: Prevents scratches and impacts from furniture moving or cleaning, extending wall lifespan.

- Waterproof and Moisture-Proof Barrier: In bathrooms and kitchens, it blocks ground moisture from penetrating walls, reducing mildew risks.

- Hide Pipelines and Gaps: Some skirting designs include slots to conceal weak current pipelines like wires and network cables, keeping spaces tidy while covering construction gaps between floors and walls.

5. Cost-Effectiveness

- Although initial costs are slightly higher than PVC or wooden skirting, aluminum alloy's weather resistance and anti-aging properties ensure a service life of over 20 years (wooden skirting lasts about 5-10 years), making it more cost-effective overall—especially for high-end residential, office, and commercial spaces requiring durability.

Key words:

Aluminum alloy skirting

Previous:

Next:

Application description:

The company is mainly committed to automotive parts aluminum profiles, radiator aluminum profiles, industrial automation aluminum profiles, rail vehicle structure aluminum profiles, solar photovoltaic bracket frame aluminum profiles, power supply box aluminum profiles, linear module aluminum profiles, machinery and equipment structural engineering, such as industrial aluminum profiles, aluminum products, design and development and production, after more than 20 years of development by domestic and foreign customers, highly trusted by the majority of customers. Can provide CNC machining customized for a variety of non-standard equipment processing parts, industry covering medical equipment parts, automotive modification parts, automotive precision parts, industrial equipment parts, photographic equipment aluminum alloy enclosure, all kinds of electronic products aluminum alloy enclosure, etc., can be customized to the drawing and sample.

Automotive Parts

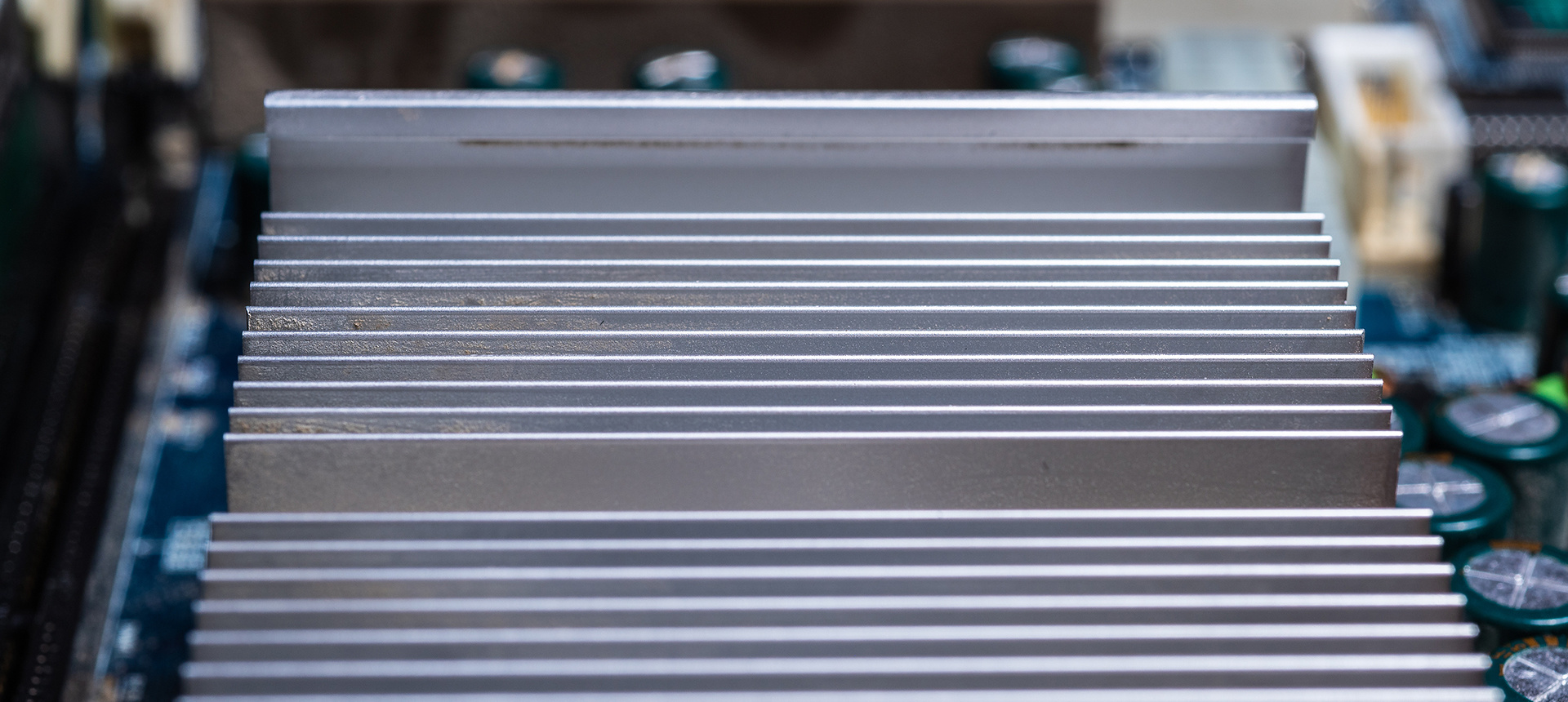

Radiator

Industrial Automation

Rail Vehicles

Factory description:

The company has 5 sets of extruders of 2000 tons-800 tons and 10 sets of CNC machining centers of 6.5 meters-2.5 meters and 850 meters, as well as 1 oxidation production line and 1 spraying production line. The company can realize one-stop service for integrated processing of aluminum profile products, which comprehensively covers aluminum extrusion, aluminum finishing, surface treatment processing and finished product processing and customization services.

Why Choose Us?

Zhengzhou Yushu New material Co., LTD

We are manufacturer and seller of industrial aluminum profiles and aluminum products with the most complete aluminum profile processing industry chain in Central Plains. The company has 5 sets of extruders ranging from 2000 tons to 800 tons, 10 sets of CNC machining centers ranging from 6.5 meters to 2.5 meters and 850 meters, as well as 1 oxidizing production line and 1 spraying production line. The company can realize one-stop service for integrated processing of aluminum profiles and products, which comprehensively covers aluminum extrusion, aluminum finishing, surface treatment processing and customized processing of finished products, etc.

20 years of experience

18000 square meters

Production capacity

AFTER-SALES TEAM

FAQ

Q

What industrial aluminium profile sizes and types can you produce?

A

Q

Do you provide customised industrial aluminium profile processing service? What is the process of customisation?

A

Q

Do the products meet international quality standards? What are the certifications?

A

Q

What is the minimum order quantity for customised products?

A

Q

What is the production lead time for customised products?

A

Q

If there is a quality problem with the product, how to deal with it?

A

Related Products

Message

Email:info@yushualu.com

Tel:+86-13938525796

Add:Unit 1, Building 3, No.19, Power Plant Road, Zhongyuan District, Zhengzhou City, Henan Province, China

Quote Now

Specialized in aluminum profiles and finishing manufacturers